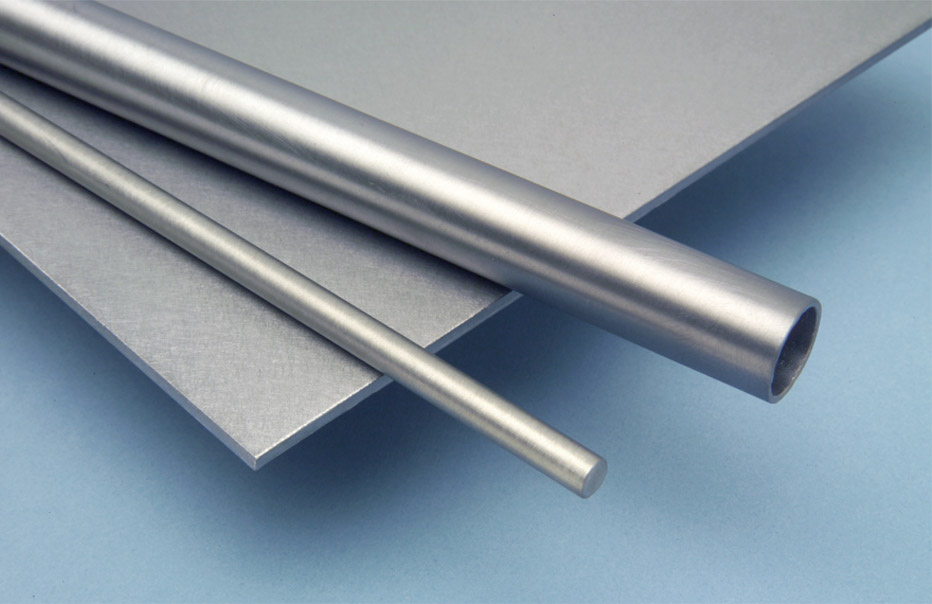

Tantalum

Metallurgical

Products

Strength, durability, ductility, corrosion resistance, thermal conductivity, and high melting point make tantalum metallurgical products highly desirable in the chemical and pharmaceutical industries and various aerospace, energy and ballistic applications.

With these characteristics, tantalum and its alloys possess a combination of properties that make them excellent materials for high temperature corrosion applications in inert atmospheres or vacuum.

Strength, Durability, and Ductility

The metal’s mechanical properties, including fatigue resistance, make tantalum equipment relatively more robust than glass or graphite systems with comparable properties in similar applications.

Thin-gauge tantalum strip can be readily deep-drawn to produce inert laboratory crucibles and cups.

High melting points allow tantalum and its alloys to have excellent thermal and mechanical properties and ease of fabrication.

Corrosion Resistance

Tantalum products provide a long service life when compared to other corrosion-resistant metals in similar applications, such as titanium, zirconium, or stainless steel.

Above 250°C, tantalum and its alloys are resistant to attack by atmospheric gases (air, oxygen, nitrogen, hydrogen, carbon monoxide, and carbon dioxide).

Thermal Conductivity and High Melting Point

Other high temperature applications include susceptors, resistance heaters, trays, thermowells, thermocouple sheaths, structural parts, crucibles, heat shields, and containers for liquid metals and vapors.

Tantalum crucibles are used for high temperature reactions, fusion, thin-film deposition, distillation and the melting of special glasses.

We offer these tantalum (Ta)

metallurgical products:

- Tantalum (Ta)

- Tantalum, 2.5% Tungsten (Ta2.5W)

- Tantalum, 10% Tungsten (Ta10W)

Available forms may include foil, sheet, plate, wire, rod, billet, tube and metallurgical grade powder.

All of our metallurgical products are manufactured at our Boyertown location in the United States.